Operations support strategy. The way work is organised impacts cost management, customer satisfaction and sustainable development.

Have a look at the image that follows. It is so true! Organisations, as they grow, they become more complex and problems begin...This is how productivity and motivation is lost... When people face repetitive problems and have to deal with cases that do not add any Value to the organisation, let alone the financial cost involved.

For public organisations, it is crucial to achieve their mission within increasing budgetary constraints, offering quality services to their customers or in other words create value. On a higher level, if an organisation achieves its performance whilst lowering its cost, jobs and salaries can be preserved.

For the private businesses alike, to stay competitive, they should seek ways to offer value to their customers. However value is created when a firm creates a competitive advantage for its buyer either by lowering its buyers’ cost or by raising its buyers’ performance, as the basic rules of marketing strategy inform us.

Lean Management Principles help you create value following the above rules of marketing strategy by providing the system and the practices to create the right internal organisation that will support the set targets without wasting resources.

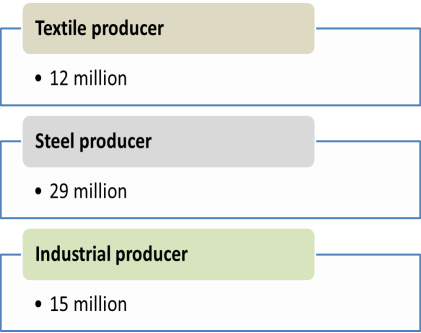

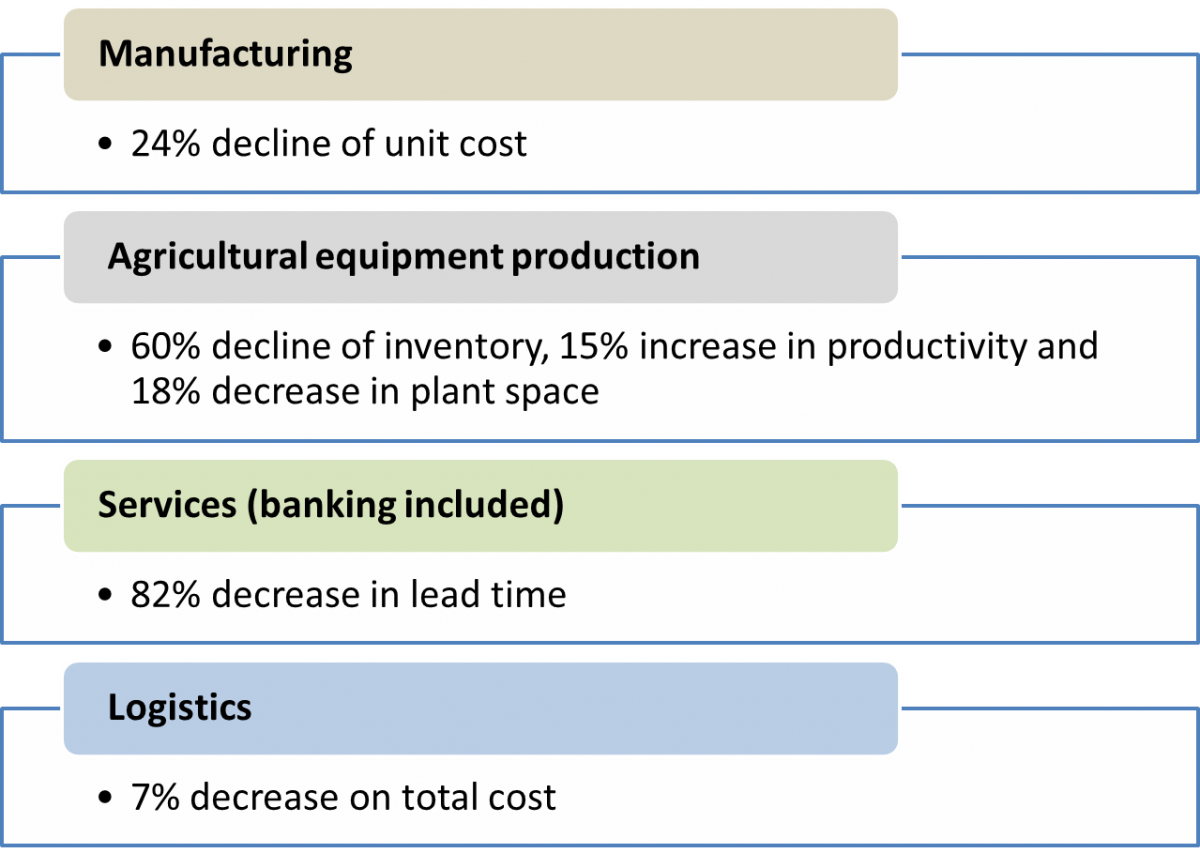

The following pictures show some of the results achieved by the Lean Institute of Turkey introducing Lean Management methods. Cost savings in USD in five years from introduction of Lean.

We are living and working in a globalised economy characterised by the interdependency of disciplines and the rapid transformation of the market place. Put simply, how work was organised 5 years ago is not the way work should be organised today. Everyday minor and major problems arise because of bad operational design which affects work motivation, execution and... profits.

At Progress Through, we believe that all private and public organisations would have a lot to benefit if their internal operational architecture was mapped and redesigned to allow improvements. Every effort to reduce any of the wastes presented in the picture does not only reduce costs but improves customer perceptions on quality and reliability.

Going Lean does not necessarily mean the redundancy of employees. It is a work philosophy. Operations are organised from the customer end backwards to reduce unnecessary tasks, allowing greater work enlargement, employee involvement and satisfaction. Easier control too.

Τraining is designed to improve the necessary predetermined technical, teambuilding and problem solving skills while operational procedures are evaluated, redesigned, implemented and re-evaluated frequently for fit for purpose.

We have assisted many organisations to save money and improve their customer’s impressions in just three months. The methodology we use depends on the operational maturity of the client and can involve simple practices such as the 5S, the Ishikawa diagrams or the A3 to more advanced like the value stream mapping, work levelling and Just in Time.

Going Lean involves both Management and Employees. Management learns how to observe the work flow work focusing on eliminating problems and waste by empowering the employees and employees learn how to communicate problems and ideas to Management, without fear.

Creating a NO BLAME culture in which everybody is looking for improvements reflects readiness and strategic capabilities difficult to copy, safe guarding your success!

We have partnered with the Lean Institute of Turkey (Member of the Global Lean Network) and Greenfile Developments Ltd in the U.K. and can offer you effective support from the simplest operational improvement initiative to a comprehensive lean transformation project!

The 7 Wastes

Decreasing or Eliminating the following wasteful cases, automatically we allow the introduction of improvements!

- Over-production

- Over-stocking

- Over-trasportation

- Over-moving

- Waiting

- Over-processing

- Errors and Mistakes

We should add an 8th waste, that of the ideas and the extra effort (from the employees) which in reality is what I call innovation. When our People spend most of their time on non value adding activities, how will innovation be truly achieved?

Lean Principles

- Understand and Satisfy your customer's needs

- Create Value for your Customer

- Improve your operations without increasing your cost

- Respect your People

- Cooperate closely with your suppliers

- Do not stop learning

Respect your People

Innovation can be achieved via new technologies but it takes a good business model and organisational (individual and team) effort to turn it into a positive result. Lean organisations facilitate teamwork, positive engagement, open communications and problem solving. Everyone is encouraged to contribute and improve on a personal level. Getting and providing feedback on the work is also encouraged by managers and employees alike and last but not least, everyone shapes his/her vision at work which includes the whole organisation and not just his/her own piece of work.

The Profit Fallacy

Most of the managers follow the old method of setting the sale price by calculating the cost and then adding on a margin of profit. Whilst this is not totally wrong (although it is not the best model of pricing), in today's marketplace how can anyone predict well enough the right profit margin let alone competitors' price wars and the effects of a turbulent environment.

So, it is the cost element that needs to be taken into consideration and pursue its continuous reduction, eliminating organisational waste (please see above the 7 wastes)